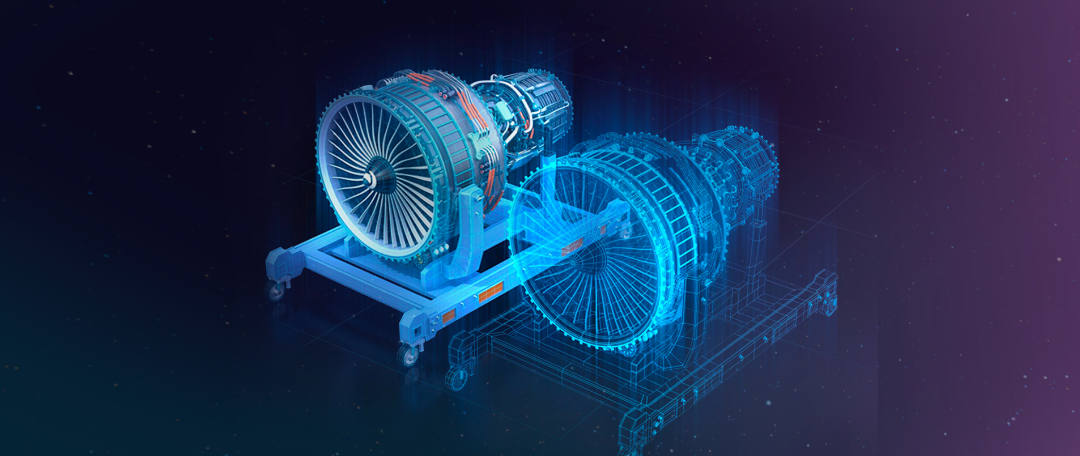

A relatively newer technology, digital twins are becoming immensely popular in industries such as construction and real estate, especially with the advent of smart buildings. Following in their footsteps, other sectors, such as energy and transportation, are also following suit.

Once an extension of the Internet of Things (IoT), digital twins are becoming an industry in the era where Web3 development is expected to make strides. However, what are digital twins, and how to build a digital twin? We will uncover such details here in this step-by-step guide.

What is a Digital Twin & Why is It So Popular?

A digital twin is a virtual representation of a physical object, system, or process that enables real-time performance monitoring, analysis, and optimization. It uses sensor data, machine learning algorithms, and other advanced technologies to create a digital replica of the physical object or system, which can be used to simulate and test different scenarios, identify problems, and improve overall performance.

Benefits of Building Digital Twins – Why Consider Digital Twins?

Digital twins, like other new technological inventions, come with their own set of benefits. Here are some of the reasons and benefits why you should go for digital twins:

- Improved performance: Digital twins can help identify problems in a physical system before they occur, enabling proactive maintenance and repairs.

- Better decision-making: With real-time data and insights, digital twins can be used to make informed decisions about the physical system. This can help optimize performance, reduce downtime, and increase efficiency.

- Reduced costs: By optimizing the use of resources, reducing waste, and minimizing downtime, digital twins can also help avoid costly repairs and replacements by identifying potential problems early.

- Increased innovation: By simulating and testing different scenarios, digital twins enable experimentation and innovation without the risk of disrupting the physical system.

- Improved collaboration: Digital twins can be shared and accessed by different stakeholders, enabling better collaboration and communication across teams and organizations.

Common Use Cases of Digital Twins

Digital twins have the potential to revolutionize various industries by providing real-time insights, optimizing performance, reducing costs, and improving sustainability and safety, and they have various applications in a number of industries. Some of the common use cases of digital twins include:

- Manufacturing: to create virtual replicas of manufacturing plants, which can help in optimizing the manufacturing process, reduce downtime, and improve efficiency.

- Construction and Real Estate: to create virtual models of buildings and infrastructure, which can help plan and design more efficient and sustainable structures.

- Energy: to create virtual models of power plants, wind farms, and other energy infrastructure, which can help in optimizing their performance and reducing costs.

- Transportation: to create virtual models of vehicles and transportation systems, which can help improve their efficiency, safety, and reliability.

- Smart cities: to create virtual models of cities and urban infrastructure for improved city planning and maintenance.

What to Consider Before Building Digital Twins?

Before you embark on building digital twins, it is essential to cross the following consideration points off your checklist.

Purpose

Determine the specific purpose of the digital twin, including the problem it is intended to solve, the data required, and the level of detail needed. This will help to ensure that the digital twin is tailored to the specific use case and provides the desired outcomes.

Data Availability

Assess the availability and quality of data needed to build the digital twin. Consider how the data will be collected, stored, and processed and any data privacy and security concerns.

Technology Requirements

Determine the technology infrastructure and software tools required to build and deploy the digital twin. Consider factors such as compatibility with existing systems, scalability, and maintenance requirements.

Resources

Assess the resources, including personnel and budget, required to build and maintain the digital twin. Consider the expertise required, such as data science, software engineering, and domain knowledge. While the benefits of web3 and digital twins may appear intriguing at best, resource constraints can act as a barrier to achieving their full potential.

Governance

Develop a governance plan to manage the digital twin, including data access, security, and ownership. Consider legal and regulatory requirements, as well as ethical and social implications.

Stakeholder Engagement

Engage stakeholders, including end-users, customers, and subject matter experts, to ensure that the digital twin meets their needs and expectations. Consider how to involve stakeholders in the digital twin’s design, development, and testing.

How to Build a Digital Twin? Step-by-Step Plan

Now that we have discussed the various applications and use cases of digital twins, we can move on to the procedure involved in building digital twins. You can build a digital twin through three technologies:

- Matterport

- Azure Digital Twins

- AWS Twinmaker

How to Build a Digital Twin with Matterport?

Matterport is a platform for creating digital twins of physical spaces, including buildings, rooms, and facilities. Here are the general steps involved in building a digital twin with Matterport:

Capture 3D data:

The first step is to capture 3D data of the physical space using a Matterport camera or a compatible 360-degree camera. Matterport cameras are specifically designed for this purpose, but you can also use other compatible cameras. The camera will capture a 3D scan of the physical space and generate a digital model.

Upload the 3D data to Matterport:

Once you have captured the 3D data, you need to upload it to Matterport’s cloud-based platform. This will allow you to access and manipulate the digital model of the physical space.

Customize the digital twin:

After uploading the 3D data, you can customize the digital twin by adding annotations, notes, and other information. This can include data such as room dimensions, furniture placement, and other details.

Share the digital twin:

Finally, you can share the digital twin with others, such as stakeholders, clients, or team members. This can be done through a web-based interface or through a mobile app. Matterport also provides various tools and features for collaboration, such as real-time commenting and project management.

Some additional considerations when building a digital twin with Matterport include:

- Using Matterport’s 3D Showcase to create a web-based walkthrough of the digital twin.

- Integrating the digital twin with other platforms or software, such as BIM tools, CAD software, or virtual reality systems.

- Using Matterport’s embedded analytics tools to monitor and optimize the performance of the physical space, such as occupancy tracking, heat mapping, and usage patterns.

How to Build a Digital Twin with Microsoft Azure?

Step #1 Create an Azure IoT Hub:

The first step in building a digital twin with Azure is to create an Azure IoT Hub. This hub will be a central location to connect and collect data from the physical system. You can create an IoT Hub using the Azure Portal or Azure CLI.

Develop an Azure Stream Analytics job:

Next, you need to develop an Azure Stream Analytics job to analyze and transform the data collected from the IoT Hub. This involves defining the input and output sources for the job and defining the queries to transform the data.

Create an Azure Digital Twins instance:

After developing the Stream Analytics job, you need to create an Azure Digital Twins instance to model the physical system and integrate it with the data processed by the Stream Analytics job. This involves defining the spatial and non-spatial models for the digital twin.

Use Azure IoT Edge to deploy the digital twin:

Finally, you can use Azure IoT Edge to deploy the digital twin to the physical system for monitoring and analysis. IoT Edge allows you to deploy the digital twin locally to the devices in the physical system, which can help reduce latency and improve the overall performance of the digital twin.

Some additional considerations when building a digital twin with Azure include:

- Defining the telemetry and device messages to collect data from the physical system.

- Defining the Azure Stream Analytics query language and syntax to transform the data collected from the physical system.

- Creating a spatial model and a non-spatial model for the digital twin to provide a complete picture of the physical system.

- Using Azure Time Series Insights to store and analyze the historical data collected from the physical system.

How to Build a Digital Twin with AWS Twinmaker?

AWS TwinMaker is a service offered by Amazon Web Services (AWS) that allows you to create and manage digital twins of your physical assets. Here are the general steps involved in building a digital twin with AWS TwinMaker:

Set up an AWS account:

The first step is to set up an AWS account if you don’t already have one. Once you have an account, you can access AWS TwinMaker and other AWS services.

Install and configure the AWS IoT Greengrass Core:

Next, you need to install and configure the AWS IoT Greengrass Core on your physical device. The Greengrass Core provides a local computing and messaging infrastructure to collect data from the device and send it to the cloud.

Develop an AWS Lambda function:

After installing the Greengrass Core, you need to develop an AWS Lambda function that will run on the Greengrass Core. This function will collect data from the physical device and send it to AWS TwinMaker for analysis and visualization.

Configure AWS TwinMaker:

Once the Lambda function is developed, you need to configure AWS TwinMaker to create a digital twin of the physical device. This involves defining the device’s characteristics, such as its properties, actions, and events.

Connect the physical device to AWS TwinMaker:

After configuring AWS TwinMaker, you need to connect the physical device to the digital twin. This involves registering the device with AWS IoT and configuring the device’s IoT policy and certificates.

Visualize and analyze the digital twin:

Finally, you can use AWS services such as Amazon QuickSight or Amazon SageMaker to visualize and analyze the data collected from the digital twin. This can help you monitor and optimize the performance of the physical system.

Some additional considerations when building a digital twin with AWS TwinMaker include:

- Defining the device shadow for the digital twin to provide a real-time view of the physical device.

- Using AWS IoT Analytics to store and analyze the historical data collected from the physical device.

- Integrating the digital twin with other AWS services such as AWS IoT Core, AWS IoT Analytics, and AWS Lambda for additional functionality.

Concluding Thoughts

Digital twin technology is still very much new, which means that any organization that invests in it will have a first-mover advantage in the long run. However, one must also consider that digital twin development can only be best done by a technology solutions provider that has expertise in such a domain, such as a Web3 development service. Before diving into creating a digital twin, consult with an organization and see if the solution is even viable in your use case.

FAQs related to Building a Digital Twin

Many software tools and platforms can be used to create digital twins, depending on the specific use case and requirements. Here are some examples:

- Azure Digital Twins

- AWS Twinmaker

- Matterport

A digital twin does not necessarily require AI. While AI can be used with a digital twin to enhance its capabilities and enable advanced analytics, it is not a necessary component.

The three primary types of digital twins include:

- Component twins: digital representations of individual components or parts within a physical system. They provide detailed information about the component’s properties, behavior, and interactions with other components and prove helpful in optimizing complex systems’ design, performance, and maintenance by enabling detailed analysis of each component’s role and impact.

- Asset twins: digital representations of physical assets such as buildings, machines, or vehicles. They provide detailed information about the asset’s condition, performance, and maintenance history, enabling predictive maintenance, remote monitoring, and optimization of asset utilization.

- Systems twins, also known as unit twins: digital representations of entire physical systems, including all the components and subsystems. They provide a comprehensive view of the system’s behavior and performance, enabling optimization of system design, performance, and maintenance. System twins are handy for complex systems with many interacting components, such as industrial processes or transportation systems.